Our story

Founded in 1963

The company initially specialized in wood products for cheese manufacturers (e.g. shelving, packaging).

In the 1970s

AVRILLON moved towards producing specialized machinery in stainless steel with its first investment in computer-aided design (CAD) and the opening of a design department.

In 1980

The company combined stainless steel machinery with automation to become a leading player in the automation of repetitive tasks for cheese manufacturers.

Late 1990s

The company diversified to provide solutions to the surface treatment industry, in particular for anodizing aluminium.

Today

We provide specialized machinery for mechanization and robotization to cheese manufacturers and for surface treatment.

We also offer a range of standard equipment for cheese manufacturers.

Expertise

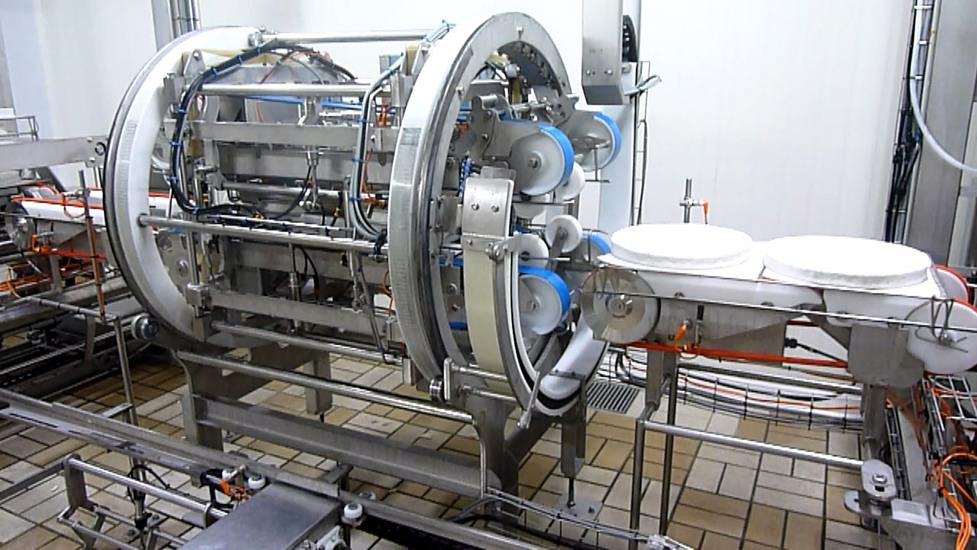

Cheese making

Our areas of operation start with cheese demoulding and stop at packaging.

Between these two stages, we can supply machinery or complete production lines that enable you to:

- Stack/unstack, transport, turn and generally handle cheese racks, stacks, pallets, storage racks, draining mats, baskets, bottom plates, aging boards etc.

- Condition cheeses, demould, turn, detach them, wash, salt/brine, cover with plastic wrap, scrub etc.

- Clean equipment: single or stacked cheese racks, pallets, palbox containers, aging boards.

- Make workstations more ergonomic.

Surface treatment

From initial study to deployment of your installation, the AVRILLON team gives you the benefit of its experience to best meet your needs and improve productivity.

- We can automate and/or robotize the processes of part assembly/disassembly.

- Our solutions cover the areas of automated production lines, the integration of vision-guided robots, mechanized parts assembly, material handling (automated or manual hoists), heating chambers, and washers.

Values & Organization

CREATIVITY

We continuously innovate to address

specific challenges

RESPONSIVE

AVRILLON’s size

makes it agile and adaptible,

and entirely at your service

GUARANTEED RESULTS

Equipment installations need to satisfy our clients,

whatever the challenges we face

Our organization

- Design department that uses SOLDWORKS for design and COSMOSWORKS for size calculations.

- Automation, programming and wiring carried out by a multidisciplinary team which specializes in using SCHNEIDER and SIEMENS automation systems.

- Machining of parts in our machine shop equipped with a machining center, CNC lathes, cutting, bending and punching equipment etc.

- Mounting of sub-assemblies and overall assembly by our team of welder-assemblers. Reading of plans with E-DRAWING PRO.

- TIG or MIG welding, sanding and passivation done internally.

Our objectives

- Design machinery adapted to meet YOUR needs with the aim of building long-term, trusting partnerships with our clients.

- Control each step of the production of your machinery in-house to be better able to respond if your system needs to evolve.

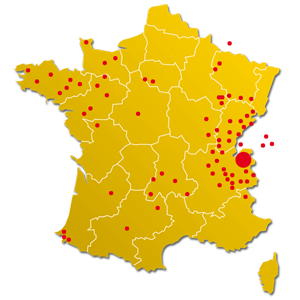

Some of our clients

- AGOUR

- ARNAUD

- BEILLEVAIRE

- BONGRAIN/SAVENCIA

- CHABERT

- CHAVEGRAND

- COOP. DE MOUTIERS

- COOP. DE THONES

- CREMO (SUISSE)

- EMMI (SUISSE)

- ENTREMONT

- ERMITAGE

- FRUITIERE DE DOMESSIN

- GABRIEL COULET

- GUILLOTEAU

- HENRI HUTIN

- H. TRIBALLAT

- JACQUES DELIN

- LA COMPAGNIE DES FROMAGES ET RICHEMONTS

- LACTALIS

- LAÏTA

- LES FROMAGERIES OCCITANES

- LINCET

- LIVRADOIS

- MAITRES LAITIERS DU COTENTIN

- MILLERET

- OLGA

- ONETIK

- PACCARD

- PIERUCCI

- SCHMIDHAUSER

- VERNIERES FRERES